You use a Class D fire extinguisher to safely put out fires involving combustible metals like magnesium, titanium, sodium, and lithium that react violently with water or standard extinguishing agents.

These extinguishers apply specialized dry powders that smother flames and absorb heat without scattering burning metal particles. This prevents dangerous explosions or fire spread.

They’re essential in industrial settings where reactive metals are present. Understanding how and where to use them properly is key to effective fire suppression and safety.

Key Takeaways

- Class D extinguishers are used to safely extinguish fires involving combustible metals like magnesium, titanium, sodium, and potassium.

- They deploy specialized dry powders that smother metal fires by isolating fuel from oxygen without causing violent reactions.

- Standard extinguishing agents like water or foam are dangerous on metal fires and can cause explosions or spread burning metal.

- Application requires gentle, controlled powder dispersion aimed at the fire base to avoid scattering burning metal particles.

- Commonly used in industrial settings such as machine shops, laboratories, and manufacturing plants handling reactive metals.

Types of Fires That Require Class D Fire Extinguishers

Fires involving combustible metals demand specialized extinguishing methods. That’s where Class D fire extinguishers come into play.

Combustible metal fires require unique extinguishing techniques, making Class D fire extinguishers essential.

You’ll encounter these extinguishers specifically designed to combat fires fueled by combustible metals in their incipient stage. These fires differ markedly from typical Class A, B, or C fires because combustible metals can react violently with water or common extinguishing agents.

When you face a fire fueled by metals that ignite easily and burn intensely, standard extinguishers won’t just fail; they may worsen the situation. Class D extinguishers use dry powders that smother the fire, isolate the fuel from oxygen, and absorb heat.

This effectively controls these highly reactive fires. You’ll find these extinguishers indispensable in environments where combustible metal fires pose a unique and dangerous challenge. Specialized dry powders, such as sodium chloride-based agents, are required for effective Class D fire suppression and are distinct from typical dry chemical agents.

Combustible Metals Targeted by Class D Fire Extinguishers

Several combustible metals demand the specialized approach of Class D fire extinguishers due to their intense reactivity and flammability.

You’ll encounter metals like magnesium, titanium, sodium, and potassium, all prone to violent ignition.

Aluminum, lithium, zirconium, and zinc also fall under this category, including their alloys.

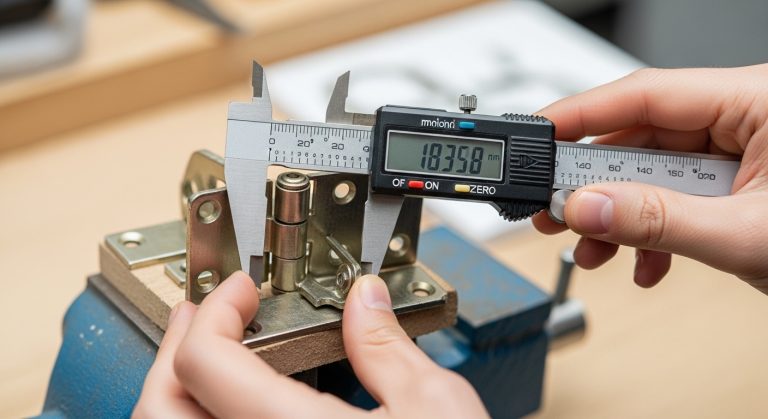

Additionally, metal fines, shavings, and dust generated during machining processes present significant fire hazards.

These metals react violently with water and ordinary extinguishing agents, so you must utilize Class D extinguishers specifically designed for them.

Their extreme reactivity requires precise handling to prevent explosions or fire spread.

Understanding which metals you’re working with guarantees you choose the correct extinguisher and maintain safety in industrial or laboratory environments where combustible metal fires might occur.

Using the right extinguisher interrupts the chemical chain reaction, which is essential to safely stop these specialized fires.

How Class D Fire Extinguishers Safely Put Out Metal Fires?

When tackling combustible metal fires, Class D fire extinguishers deploy specialized dry powders that interrupt the combustion process without triggering violent reactions.

You’ll find agents like powdered graphite, granular sodium chloride, or copper-based fragments that smother the fire by forming a barrier between the metal fuel and oxygen.

This barrier isolates the combustible material, cutting off its oxygen supply and preventing further oxidation.

Additionally, these powders absorb heat from the reaction zone, lowering temperatures and reducing the risk of reignition.

You must apply the extinguishing agent gently to avoid scattering burning metal particles, which could exacerbate the fire.

For effective use, always aim the nozzle low at the base of the fire and maintain a safe distance while applying the extinguishing agent.

Where to Find Class D Fire Extinguishers in Industrial Settings?

Understanding how Class D fire extinguishers suppress metal fires helps clarify why their placement in industrial environments matters.

You’ll find these extinguishers primarily in locations where combustible metals like magnesium, titanium, or aluminum are handled, stored, or processed.

This includes manufacturing plants, machine shops, laboratories, and warehouses dealing with metal parts or dust.

They’re strategically positioned near metal cutting or machining stations, refining and processing areas, and mining facilities to address fires at the incipient stage promptly.

Since Class D extinguishers use specialized dry powders that smother and cool metal fires without causing violent reactions, they must be accessible where metal shavings or dust accumulate.

Proper placement also ensures quick response times, reducing the risk of escalation due to environmental factors such as dust accumulation or heat buildup.

Why Other Fire Extinguishers Don’t Work on Class D Fires?

You know, using standard extinguishers on Class D fires is just not a good idea. Why? Well, water and other common agents can actually trigger some pretty violent chemical reactions with those combustible metals.

And if you expose those fires to more oxygen? Yikes! That just makes everything worse, turning a small fire into a big problem.

That’s where Class D extinguishers come into play. They handle things differently.

Instead of making the situation worse, they isolate the metal and absorb heat, all while avoiding any explosions.

Proper fire suppression techniques are crucial to prevent hazardous reactions and ensure safety.

Chemical Reactions With Water

Since combustible metals react violently with water, using standard fire extinguishers containing water or foam can trigger explosive chemical reactions that worsen Class D fires.

When metals like sodium, potassium, or magnesium contact water, they generate hydrogen gas and intense heat, often causing violent explosions or spreading burning metal fragments.

This reaction not only intensifies the fire but also endangers nearby personnel and property. You can’t rely on water-based agents because they fail to smother these fires and instead fuel them.

That’s why Class D extinguishers use dry powders that isolate the metal from oxygen and absorb heat without triggering hazardous reactions.

Understanding these chemical interactions helps you avoid dangerous mistakes and guarantees you apply the correct extinguishing method for combustible metal fires.

Proper selection and use of fire extinguishers are crucial, since using the wrong type can exacerbate hazards similar to how water can worsen metal fires, highlighting the importance of fire extinguisher classification.

Oxygen Exposure Risks

Why do common fire extinguishers fail against Class D fires? The key lies in oxygen exposure.

Combustible metals like magnesium or sodium react violently when exposed to oxygen.

Standard extinguishers often fail because they don’t effectively isolate the metal from air. Instead, they may disperse burning particles or introduce water, intensifying the fire.

You need a Class D extinguisher that applies a dry powder agent, forming a barrier that deprives the fire of oxygen and absorbs heat.

This prevents the metal’s oxidation and halts the combustion chain. Using other extinguishers risks exposing the reactive metal directly to oxygen, fueling the fire rather than suppressing it.

Understanding this oxygen exposure risk is critical for safely managing metal fires. For enhanced safety, it is important to combine detection methods to identify and prevent hidden ignition sources that could trigger metal fires.

Extinguisher Reaction Differences

Although common fire extinguishers are designed to tackle various fire classes, they fail on Class D fires because their agents react adversely with combustible metals.

For example, water-based or foam extinguishers cause violent chemical reactions, leading to explosions or spreading burning metal particles.

Carbon dioxide or dry chemical extinguishers don’t form the necessary smothering barrier and can scatter metal dust, intensifying the fire.

Class D extinguishers use specialized dry powders like sodium chloride or copper-based agents that absorb heat and isolate the metal from oxygen without triggering dangerous reactions.

You must use these powders carefully, applying them gently to avoid dispersing combustible metal particles.

Understanding these reaction differences is critical to extinguishing metal fires safely and effectively, preventing escalation and ensuring your safety.

How to Use a Class D Fire Extinguisher Without Spreading Fire?

When you’re using a Class D fire extinguisher, it’s super important to be gentle when dispensing the agent. You want to avoid scattering any combustible metal particles that could make things worse.

Instead, focus your application on a specific area to really isolate the fire. This way, you can put out the flames without spreading any burning material around.

And remember, don’t get too aggressive with your spraying! Keeping it controlled not only helps with effective suppression but also lowers the chances of reigniting the fire.

Just take a deep breath and approach it calmly; your careful handling can make all the difference. Additionally, having continuous monitoring systems in place can help ensure early detection of hazards that might escalate to fires.

Gentle Dispensing Technique

To put out a Class D fire effectively, you need to dispense the extinguishing agent gently to avoid scattering combustible metal particles and intensifying the fire.

Approach the fire slowly, aiming the nozzle at the base of the flames without forceful bursts. Use a steady, controlled flow of the dry powder to blanket the burning metal, ensuring the agent covers the fuel uniformly.

Avoid excessive pressure or rapid sweeping motions, which can disperse hot metal fragments and worsen the situation. Maintain a safe distance, adjusting as the fire subsides, and continue gentle application until the fire is fully smothered.

This measured dispensing technique isolates oxygen and cools the reaction zone without spreading combustible materials. This is critical for safely managing metal fires with a Class D extinguisher.

Regular maintenance and monthly testing of fire safety equipment are essential to ensure reliable operation when needed.

Avoid Metal Scattering

You’ll need to carefully control your movements to avoid scattering combustible metal particles while using a Class D fire extinguisher. Sudden or forceful motions can disperse burning metal dust or shavings, spreading the fire.

Apply the extinguishing agent softly and steadily, targeting the base of the flames to smother fuel without agitation.

| Do’s | Don’ts |

|---|---|

| Apply powder gently | Avoid rapid, sweeping sprays |

| Direct agent at fire base | Don’t pour or dump powder |

| Maintain steady hand control | Don’t disturb metal debris |

| Use recommended nozzle range | Avoid high-pressure blasts |

These techniques isolate oxygen, prevent reignition, and minimize reactive hazards. This ensures effective suppression without exacerbating the fire. Proper training and adherence to fire safety standards are essential to using Class D extinguishers safely and effectively.

Controlled Application Area

Controlling the application area during Class D fire extinguisher use directly supports preventing metal particle dispersion discussed earlier.

You must apply the extinguishing agent precisely over the burning metal, avoiding excess force that could scatter combustible particles.

Position yourself upwind and maintain a safe distance to minimize inhalation hazards and prevent spreading the fire.

Use a gentle, sweeping motion starting at the fire’s base, gradually covering the affected area without disturbing unburned metal.

Avoid aggressive spraying or aiming from too close, as this risks dispersing hot metal dust or shavings.

By confining the agent to the immediate fire zone, you isolate the fuel source effectively, ensuring oxygen is cut off and heat is absorbed without reigniting adjacent materials.

This controlled technique is essential for safely extinguishing Class D fires.

Frequently Asked Questions

How Often Should Class D Fire Extinguishers Be Inspected and Maintained?

You should inspect Class D fire extinguishers monthly to make certain they’re fully charged, accessible, and undamaged.

Perform a thorough maintenance check annually, including verifying the dry powder agent’s condition and checking for any corrosion or clogging.

Follow manufacturer guidelines for servicing, as improper handling can reduce effectiveness.

Keep detailed records of inspections and maintenance to comply with safety standards, ensuring the extinguisher functions properly during a combustible metal fire emergency.

Can Class D Extinguishers Be Used on Mixed Metal and Chemical Fires?

You shouldn’t use Class D extinguishers on mixed metal and chemical fires because they’re designed specifically for combustible metal fires only.

Using them on chemical fires or mixed fires may worsen the situation, as they won’t effectively suppress non-metal components. For mixed fires, you need a tailored approach with appropriate extinguishing agents for each fuel type.

Always follow manufacturer guidelines and assess the fire class before selecting an extinguisher.

Are There Size Variations for Class D Extinguishers for Different Facilities?

When it comes to Class D extinguishers, size does matter.

You’ll find various sizes tailored to different facilities, from small labs to large industrial plants.

The extinguisher’s capacity depends on the potential fire risk and metal quantities present.

Smaller units suit confined spaces, while larger ones cover expansive areas with heavy metal dust or shavings.

Always match the extinguisher size to your specific hazard for effective fire control.

What Training Is Required to Operate a Class D Fire Extinguisher Safely?

You need specific training to operate a Class D extinguisher safely. This includes understanding combustible metal hazards, recognizing fire stages, and proper extinguisher handling to avoid scattering metal particles.

You’ll learn to apply the dry powder gently, smothering the fire without causing explosions. Training covers manufacturer instructions, correct approach angles, and emergency procedures.

Familiarity with the facility’s metals and risks is essential for effective, safe use.

How Long Does the Extinguishing Agent Last Once the Extinguisher Is Activated?

Once you pull the trigger, the extinguishing agent lasts just long enough to smother the fire’s hungry flames—typically around 10 to 30 seconds depending on the extinguisher size.

It blankets combustible metals swiftly, cutting off oxygen and absorbing heat.

You’ve got to act decisively; the agent’s limited duration means you must apply it smoothly and precisely to prevent reignition.

Dispersing it too quickly risks scattering reactive metal particles.

Final Word: Metal Fires Need Specialized Protection

When dealing with combustible metal fires, you need a Class D fire extinguisher because standard extinguishers just won’t cut it.

Did you know that metal fires can burn at temperatures exceeding 3,000°F? Using the wrong extinguisher could make things worse. Class D extinguishers use specialized dry powders to smother these intense fires safely.

So, always make sure you have the right extinguisher on hand in industrial settings where metal fires pose a real risk.