When you work with low voltage wire, you’re typically handling cables rated up to 1000 volts AC or 1500 volts DC. These wires are designed for applications like security systems, HVAC controls, and data networks.

They use insulation standards focused on safety and flexibility, meeting codes such as NEC NFPA 70 and IEC regulations. Low voltage wiring involves specific materials and gauges suited for limited-energy circuits to reduce shock and fire risks.

Understanding these parameters helps you select the right wire for your project’s needs.

Key Takeaways

- Low voltage wire typically carries voltages up to 50 V AC or 120 V DC for safety and regulatory definitions.

- Common standards define low voltage as circuits operating below 1000 V AC or 1500 V DC maximum.

- Low voltage cables use insulation rated for up to 600/1000 V to ensure durability and safety in typical applications.

- These wires are used in applications like security systems, HVAC controls, and LED lighting requiring limited electrical energy.

- Regulatory codes like NEC NFPA 70 and IEC standards specify wire construction and voltage limits for low voltage wiring.

What Voltage Levels Define Low Voltage Wire?

Although definitions vary by standard, low voltage wire generally operates at voltage levels markedly lower than standard power circuits.

You’ll find electricians typically define low voltage as 50V AC or less, or 120V DC or less.

The National Electrical Code (NEC) classifies Class 2 circuits at a maximum of 60V DC or 30V RMS AC with current limitations.

Internationally, the IEC sets low voltage from 50V to 1000V AC or 120V to 1500V DC, while extra-low voltage is under 50V AC or 120V DC.

The British Standard BS 7671 considers low voltage exceeding 50V AC or 120V DC but not above 1000V AC or 1500V DC.

These voltage ranges help you select appropriate wiring for safety and performance within specific electrical applications.

Understanding electromagnetic interference is important when considering voltage levels in wiring systems.

How Is Low Voltage Wire Different From High Voltage Wire?

You might’ve noticed that low voltage wire usually handles up to 1000V AC or 1500V DC. On the other hand, high voltage wire goes well beyond those levels.

When it comes to insulation, low voltage cables are designed with flexibility and safety in mind. This helps to minimize the risk of shock.

In contrast, high voltage cables need thicker and more robust insulation because they’ve to endure greater electrical stresses.

Proper preparation and handling of electrical components, including cables, are essential for reducing environmental impact and ensuring safety.

Voltage Range Differences

When comparing low voltage wire to high voltage wire, the primary distinction lies in their voltage ratings and corresponding insulation requirements.

Low voltage wires typically handle up to 1000V AC or 1500V DC, conforming to standards like IEC and NEC. High voltage wire operates beyond these limits, demanding more robust insulation and safety measures.

Understanding these ranges helps you select appropriate cables for your application.

| Voltage Type | Voltage Range | Typical Applications |

|---|---|---|

| Low Voltage | 0–1000V AC / 0–1500V DC | Security systems, telecom, lighting controls |

| Extra-Low Voltage | <50V AC / <120V DC | Doorbells, thermostats, sensors |

| High Voltage | >1000V AC | Power transmission, industrial equipment |

Safety And Insulation

Since low voltage wire operates at markedly lower voltages, typically up to 1000V AC or 1500V DC, it requires insulation and safety features tailored to reduce shock and fire risks without the extensive protective measures high voltage wire demands.

You’ll notice low voltage cables often use insulation materials like XLPE or PVC with flame-retardant ratings, such as Eca, that provide sufficient heat resistance and durability for their applications.

Unlike high voltage wire, which needs thick, multi-layered insulation and shielding to prevent arcing and catastrophic failure, low voltage cables rely on current-limiting designs and reduced voltage thresholds to enhance safety.

This means you can install low voltage wiring with less stringent clearance and insulation thickness requirements while still meeting NEC and IEC standards for shock protection and fire resistance.

However, even low voltage wiring can pose risks if there are loose connections or damaged insulation, which may lead to sparking or arcing hazards that require professional inspection.

Common Applications for Low Voltage Wiring

Low voltage wiring powers a wide array of essential systems in residential and commercial environments. It enables efficient control and communication with minimal electrical risk.

Low voltage wiring supports critical systems with safe, efficient control and communication in homes and businesses.

You’ll find these wires in security systems, powering cameras and alarms with voltages typically under 50V AC or 60V DC. They also operate HVAC controls like thermostats, ensuring precise temperature regulation.

In lighting, low voltage wiring supports dimmers and LED fixtures, enhancing energy efficiency. For networking, Cat5e or Cat6 cables handle data transmission at 100-600V rating, vital for internet and Wi-Fi setups.

Telecom applications rely on low voltage circuits between 12V and 48V DC for phones and intercoms. Control wiring in industrial automation also uses 18-22 AWG low voltage cables, ensuring safe and reliable signal transmission.

Proper installation includes avoiding areas with excessive moisture or electromagnetic interference to maintain reliable sensor performance.

Important Safety Standards for Low Voltage Wire

When it comes to ensuring the safety of low voltage wire, it’s crucial to follow some key regulatory standards. For starters, you’ll want to look into NEC NFPA 70 and IEC 60502-1. These guidelines are really important because they help define the voltage limits, which typically go up to 1000V AC or 1500V DC.

But that’s not all; they also set current restrictions for Class 2 and Class 3 circuits. Understanding these parameters is essential. It not only helps you pick the right wiring but also ensures that you meet both performance and safety requirements.

So, keeping these standards in mind can really make a difference in your wiring projects! Additionally, ensuring proper ventilation and maintenance of electrical installations can prevent hazards related to malfunction and carbon monoxide exposure.

Key Regulatory Standards

When handling low voltage wire, adhering to key regulatory standards guarantees both safety and compliance. You must follow established codes to guarantee proper insulation, conductor sizing, and fire resistance, minimizing risks of electrical hazards.

The primary standards to take into account include:

- NEC NFPA 70: Governs wiring methods and materials for circuits up to 1000V, including low voltage.

- IEC 60502-1: Specifies power cable construction and insulation for rated voltages of 0.6/1kV.

- UL Certification: Confirms cables meet rigorous safety and performance testing.

- IEC 60228: Defines conductor properties and classifications for insulated cables.

- IEC 60364-4-41 & IEC 61140: Set safety requirements for shock protection in low voltage installations.

Strict compliance with these standards guarantees your low voltage wiring performs safely and reliably under expected conditions. Additionally, understanding kinetic energy transfer principles is crucial for minimizing electromagnetic interference in cable design.

Voltage And Current Limits

Understanding the voltage and current limits defined by safety standards helps assure low voltage wiring installations remain within safe operational boundaries.

You must adhere to definitions like NEC’s Class 2 circuits, which limit voltage to 60V DC or 30V RMS AC with restricted current to minimize shock hazards.

Similarly, IEC’s extra-low voltage category caps at 50V AC or 120V DC, ensuring safe handling.

Current limits depend on wire gauge and insulation rating; for instance, UL 508A specifies 0–20V peak at 5A or up to 42.4V peak at 100VA for low-voltage limited-energy circuits.

Exceeding these parameters risks insulation breakdown, overheating, or fire.

You need to select cables rated for the intended voltage and current per standards like IEC 60502-1 and NEC NFPA 70, ensuring compliance and safety in your wiring projects.

For applications such as smoke detectors, it is important to consider the low voltage battery types used, as these often operate within these defined voltage and current limits to maintain safety and reliability.

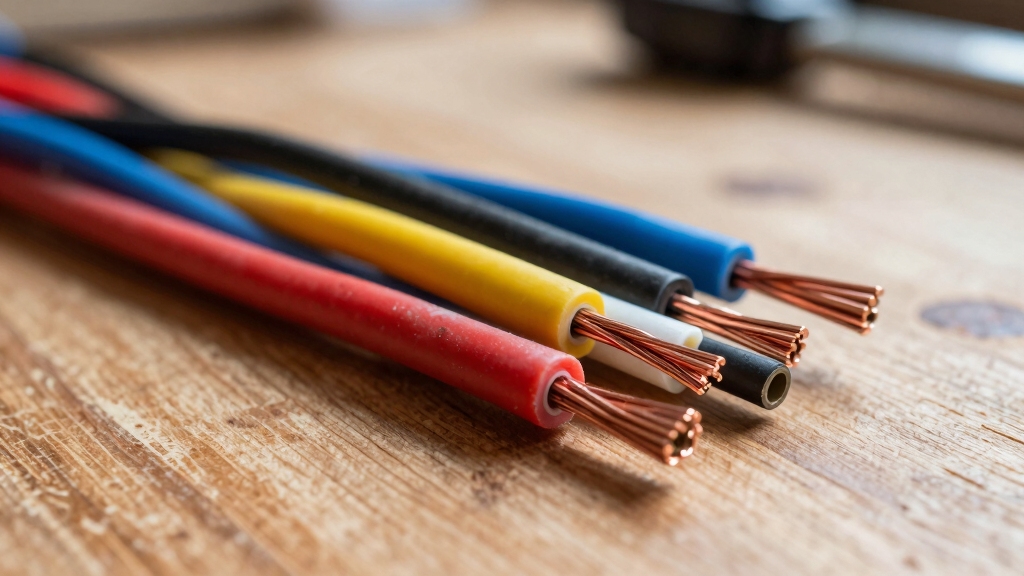

Typical Cable Types and Insulation for Low Voltage Wiring

Low voltage wiring calls for specific cable types and insulation materials designed to handle lower electrical stress while guaranteeing safety and performance.

You’ll often use cables rated for 600/1000V with insulation materials that resist heat, moisture, and mechanical damage. Common insulation types include PVC for general use and XLPE for enhanced thermal resistance.

Shielded cables reduce electromagnetic interference in sensitive systems. Here are typical options you’ll encounter:

- PVC-insulated cables: Flexible, flame-retardant, cost-effective for general low voltage applications

- XLPE-insulated cables: High thermal stability, ideal for environments with elevated temperatures

- Category 5e/6 cables: Twisted pairs with polyethylene insulation, used for data transmission

- CL2/CL3-rated cables: Suitable for in-wall installations, meeting NEC safety standards

- Shielded cables: Metal foil or braid shielding for noise reduction in control and communication wiring

Selecting the right insulation guarantees compliance and durability. Measuring installation spaces accurately and allowing for proper clearance ensures that low voltage wiring fits safely within walls or conduits without damage, following installation considerations.

How to Identify and Choose the Right Low Voltage Wire

Start by examining the voltage rating, insulation type, and application requirements to identify the right low voltage wire for your project.

Verify the wire’s voltage rating matches or exceeds your system’s maximum voltage, typically 50V AC or 120V DC for low voltage applications.

Choose insulation materials like XLPE for heat resistance or PVC for general use, considering environmental factors.

Evaluate wire gauge: 18 to 22 AWG suits most control or telecom needs, while Cat5e or Cat6 cables fit data networking.

Confirm compliance with standards such as NEC NFPA 70 and UL certification for safety and reliability.

Finally, consider installation specifics: select CL2 or CL3-rated cables for in-wall use and opt for shielded or armored cables where electromagnetic interference or physical damage risk exists.

For wiring that involves plastic components, ensure proper surface preparation techniques, like surface sanding and cleaning, to improve long-term durability and adhesion of coatings or insulation materials.

Frequently Asked Questions

Can Low Voltage Wire Be Used Outdoors Safely?

Yes, you can use low voltage wire outdoors safely if you choose cables rated for exterior use.

Look for UV-resistant insulation like XLPE or specialized outdoor-rated jackets.

Make sure the wire has proper waterproofing and corrosion-resistant features to withstand moisture and temperature changes.

Additionally, install the wire in conduit or protective tubing to prevent physical damage.

Follow local electrical codes and manufacturer guidelines to maintain safety and performance outdoors.

What Tools Are Needed to Install Low Voltage Wiring?

You’ll need wire strippers, as 18-22 AWG low voltage wires require precise insulation removal without damaging conductors.

A multimeter is essential for verifying voltage levels. Remember, many low voltage systems operate under 50V AC, reducing shock risk.

Fish tape helps route cables through walls efficiently. Additionally, a drill with appropriate bits, crimping tools for connectors, and a voltage tester guarantee safe, compliant installation.

These tools optimize accuracy and safety during setup.

How Long Can Low Voltage Wire Runs Be Without Signal Loss?

You can typically run low voltage wires up to 1000 feet without significant signal loss, but this depends on wire gauge, voltage, and application.

For data cables like Cat5e or Cat6, 328 feet (100 meters) is the IEEE standard limit to avoid degradation. Beyond that, you’ll need signal boosters or repeaters.

For power or control wiring, resistance and voltage drop increase with length, so keep runs as short as practical for reliable performance.

Are Low Voltage Wires Recyclable or Environmentally Friendly?

You might think low voltage wires aren’t recyclable due to their insulation, but many components actually are. The copper or aluminum conductors inside can be reclaimed efficiently.

However, the polymer insulation, often PVC or XLPE, requires specialized recycling processes. While these wires aren’t inherently eco-friendly, advances in recycling tech and use of flame-retardant, less toxic materials are improving their environmental impact.

Can Low Voltage Wiring Interfere With Wi-Fi or Other Signals?

Yes, low voltage wiring can interfere with Wi-Fi or other signals if improperly installed.

You should avoid running low voltage cables parallel and close to data or RF lines to minimize electromagnetic interference (EMI).

Using shielded cables, twisted pairs like Cat6, and proper grounding reduces crosstalk and noise.

Maintaining separation distances and following standards like NEC NFPA 70 assure your signals stay clean and reliable in mixed wiring environments.

Building Reliable Systems Starts with the Right Wire

Think of low voltage wire as the nervous system of your electrical setup. It is delicate yet vital, transmitting signals and power without overwhelming the circuit. Just like you wouldn’t use a heavy-duty cable to send a whisper, you need the right wire rated for low voltage to guarantee safety and efficiency.

By understanding voltage levels, insulation types, and standards, you can confidently choose the precise wiring that keeps your system responsive, reliable, and secure.